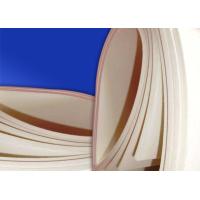

Seamless Heat Press Felt High Temperature Nomex Fiber Material

Sublimation Printing

Nomex Felt is made of imported high-temperature Nomex fiber. The

intermediate base fabric is made of polyester dry mesh and Kevlar

base. The temperature can reach 250 degrees. The late shrinkage

rate is 2%, the elongation is 3%, weight is 3000g/m2 (normal 8mm

thickness), is a special blanket for all kinds of fabrics, curtain

fabrics, decorative fabric transfer printing machines.

Base cloth high temperature resistant transfer printing blanket has

the advantages that the carpet surface is flat, the carpet body is

soft, not easy to crack, and the service life is long. After the

heat setting, the width shrinkage rate of the blanket is within 3%.

It is very popular in domestic and foreign markets.

The purpose of the sublimation felt is to press the fabric against

the printed paper, both against the heated drum. The contact

between the fabric and the printed paper needs to be long enough,

to ensure the transfer of the dyestuffs to the fabric. Heat

transfer printing is an economical way to print synthetic fabrics.

These machines can also be used for the following processes :

Laminating,or Roll to Roll printing, sublimation printing

Calendering

Placard transfer printing (banners)

These Nomex felts are used on the following machines : Klieverik,

Monti, Transmatic, Lemaire, Practix, Sorim, Studio FX, Stork,

Bates, Wuppertal, Kristall, Sublistatic, Gessner, Bizmak, S.T.M.,

Singer, KMT, MOGK, TURAL MAKINA...